Heat Resistant Cables

Home >> Heat Resistant Cables

Heat Resistant Cables Manufacturer

At MEM Industries, we specialize in manufacturing top-quality heat resistant cables designed to perform reliably in high-temperature environments. Our extensive product range includes heat resistant electrical wires, heat proof cables, and flexible cables to meet various industrial and commercial needs.

Why Choose Heat Resistant Cables?

Heat resistant cables are essential for applications where exposure to high temperatures is a concern. They are designed to maintain functionality and safety even under extreme conditions. Our heat resistant cables are engineered to ensure durability, flexibility, and performance, making them ideal for critical applications.

Benefits of Heat Resistant Cables:

- High Temperature Tolerance: Designed to withstand elevated temperatures without degradation.

- Enhanced Safety: Reduces the risk of fires and electrical failures in high-heat environments.

- Durability: Maintains integrity and performance over time, even under harsh conditions.

- Flexibility: Ensures ease of installation and use in various applications.

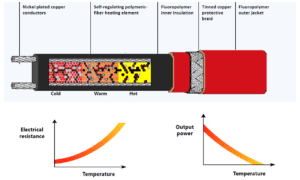

High Temperature Resistant Non Flammable Cables

- Applicable Standards : JSS: 51034, IS: 9968 (Pt-1), IS:8130-1984, BS:5308 (Pt-2) & IS:1554 (Pt-1)

- Voltage grade: upto 1100 volts

- Conductor size: 0.50, 0.75, 1.0, 1.5, 2.5, 4, 6, 10, 16, 25 sq.mm up to 240 sq.mm

- Conductor Materials: Annealed Bare Copper / Tinned Copper/ Silver plated Copper and Nickel plated Copper

- Heat Barrier Tape: Ceramic Glass Mica tape / Kapton Tape /Polyimide Tape

- Insulation : PTFE (260 deg C), FEP (205 deg C), Silicone Rubber(180 deg C), Fiber Glass (600 deg C), Ceramic Glass Mica (800 deg C)

- Screening / Shielding : Aluminium-Mylar tape with ATC drain wire / Silver Plated Copper wire braided / Nickel Plated Copper wire braided

- Armouring : Stainless Steel wire Braided type Flexible

- Inner / Outer Sheath : PTFE (260 deg C), FEP (200 deg C), Silicone Rubber(180 deg C), Asbestos Yarn (400 deg C), Fiber Glass (600deg C), Ceramic Glass Mica (800 deg C)

- Maximum Temperature with Standing Capacity : upto 800 deg C

SPECIAL FEATURES

- Available in multiple Insulations having different properties & various temperature range.

- Available from -73 deg C to 800 deg C range

- Hi Di-electric Strength

- Excellent Flame and Heat Resistant properties

- Available with Non-Flammable properties

- Available both Screen & Unscreen type

- Available both Armoured and Unarmoured type

- High Insulation Resistant

- Flexible and versatile

- High Mechanical strength

- U.V. Resistant

- Oil, Chemical, Moisture and Corrosion Resistant

- Excellent Thermal stability

- Halogen-Free Insulating materials such as PTFE / FEP/ ETFE / Silicone Rubber

SPECIAL INSULATING MATERIALS

| INSULATIONS | TEMPERATURE RANGE | PROPERTIES |

| Alumina Fiber | -73 deg C to 1200 deg C | Excellent Temperature Resistant |

| Ceramic Fiber | -73 deg C to 800 deg C | Excellent Temperature Resistant |

| Ceramic Glass Mica | -70 deg C to 800 deg C | Excellent Heat Resistant |

| Polyamide | -267 deg C to 310 deg C | Thin insulation, different colors available, Flame retardant |

| PTFE | -100 deg C to 260 deg C | High temperature resistant, Non-Flammable, Chemical and Oil resistant, excellent Di-electric strength |

| FEP | -80 deg C to 200 deg C | Chemical and Oil resistant, High Di-electric strength |

| Silicone Rubber | -40 deg C to 180 deg C | Highly flexible, Radiation resistant, high temperature resistant |

| Fiber Glass Yarn | -70 deg C to 600 deg C | High temperature resistant |

| Asbestos Yarn | -70 deg C to 400 deg C | High temperature resistant, good abrasion resistant |

HTC-909-300

Sintered PTEF – Sintered PTEF – S.S. Wire

Specification

- Voltage grade: upto 1100 volts

- Conductor: Bare Copper / Nickel Plated Copper / Silver Plated Copper

- Type: Multi Stranded Flexible

- Core Insulation: Sintered PTFE with Kapton

- Construction: Twisted cores / Laid up cores

- Outer Sheath: Sintered PTFE

- Overall Coverage: Fiber Glass Covering [Optional]

- METAL Braiding: Stainless Steel wire mesh for Mechanical protection [Optional]

Other Options

- Aluminium Mylar Tape Shield / Screen with ATC drain wire

- Overall Asbestos Braiding for Better Chemical & Heat Resistance

- Colour coding as per customised requirement

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm.

- Number of Cores available: 1C to Multicore as per customised requirement

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-918-400

Sintered PTFE – Fiber Glass – Fiber Glass – S.S. Wire

Specification

- Voltage grade up to 1100 volts

- Conductor: Bare EC Copper /Nickel Plated Copper/ Silver Plated Copper

- Type: Multi stranded flexible

- Core insulation: Sintered PTFE / Fiber Glass with high temperature varnish

- Construction: Twisted Cores / Laid up cores

- Inner jacket: Sintered PTFE & then Glass Plated Mica Tape

- Outer jacket: Fiber Glass Braiding / Asbestos Yarn Braiding

- Metal braiding: Stainless Steel wire mesh for Mechanical protection [Optional]

Other Options

- Aluminium mylar tape Shield / Screen with ATC drain wire

- Overall Asbestos Braiding for Better Chemical & Heat Resistance

- Colour coding as per customer requirement

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm.

- Number of cores available: 1C to multicore as per customer requirement

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-927-400

Sintered PTFE – Sintered PTFE – Mica – Fiber Glass – S.S. Wire

Specification

- Voltage grade : up to 1100 volts

- Conductor: Bare Copper / Nickel Plated Copper / Silver Plated Copper

- Type: Multi stranded Flexible

- Core Insulation : Sintered PTFE with Kapton

- Construction : Twisted core / Laid up Cores

- Inner jacket : Sintered PTFE Tape then Glass Mica Tape

- Outer jacket : Glass Mica Tape and then Fiber Glass with high temperature varnish

- Metal Braiding : Stainless Steel wire mesh for Mechanical protection [Optional]

Other Options

- Aluminium mylar tape Shield / Screen with ATC drain wire

- Overall Asbestos Braiding for Better Chemical & Heat Resistance

- Colour coding as per customised requirement

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm.

- Number of cores available: 1C to Multicore as per customer requirement

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-936-500

Sintered PTFE – Fiber Glass – Mica – Fiber Glass – S.S. Wire

Specification

- Voltage grade : up to 1100 volts

- Conductor: Bare Copper / Nickel Plated Copper / Silver Plated Copper

- Type : Multi stranded

- Core Insulation : Mica / Sintered PTFE / Kapton Fiber Glass with high temperature varnish

- Construction : Twisted core / laid up cores

- Inner jacket : Glass Plated Mica Tape and then Fiber Glass with high temperature varnish

- Outer jacket : Fiber Glass then Asbestos Yarn Braiding

- Metal Braiding : Stainless Steel wire mesh for Mechanical protection [Optional]

Other Options

- Aluminium mylar tape Shield / Screen with ATC drain wire

- Overall Asbestos Braiding for Better Chemical & Heat Resistance

- Colour coding as per customised requirement

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm.

- Number of cores available: 1C to Multicore as per customer requirement

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-945-600

High Temperature Copper Power Cable suitable for 600 deg C

Specification

- Voltage grade : up to 1100 volts

- Conductor: Multi stranded Annealed Electrolytic grade copper as per class – 5 of IS:8310-1984

- Primary Insulation: Mica tape then Sintered Teflon (PTFE) with Kapton

- Secondary Insulation : Heat & flame Resistant double Fiber Glass covering with heat resistance varnish

- Core Laying: Core Laid up together

- Inner Sheath: Sintered Teflon (PTFE)

- Outer Sheath: Double Mica tape, Double Fiber Glass Braiding, Asbestos Braiding

- Mechanical Protection : Stainless Steel Braided to protect the cable from Mechanical Stress

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm. from single core to multi core

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-954-800

High Temperature Copper Power Cable suitable for 800 deg C

Specification

- Voltage grade : up to 1100 volts

- Conductor: Multi stranded Annealed Electrolytic grade copper as per class – 5 of IS:8310-1984

- Primary Insulation: Mica tape then Sintered Teflon (PTFE) with Kapton

- Secondary Insulation : Heat Resistant Mica Tape and then Ceramic Fiber

- Core Laying: Core Laid up together

- Inner Sheath: Sintered PTFE then Ceramic Glass Fiber covering with Glass Mica Tape

- Outer Sheath: Double Ceramic Glass Fiber Braided

- Mechanical Protection : Stainless Steel wire Braided to protect the cable from Mechanical Stress

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm. from single core to multi core

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

At M.E.M. Industries, we specialize in manufacturing high-quality Heat Resistant Cables designed to meet the rigorous demands of various industrial and commercial applications. At M.E.M. Industries, we are committed to providing top-quality Heat Resistant Cables that meet the highest industry standards. Our extensive range of Heat Resistant Cables ensures safety, reliability, and efficiency even under extreme temperature conditions.

Here’s a detailed overview of the types and sizes of Heat Resistant Cables we offer:

Types of Heat Resistant Cables

Heat Proof Cable

- Engineered to withstand high temperatures without compromising performance, our Heat Proof Cables are ideal for environments where exposure to extreme heat is a constant challenge.

Heat Resistant Electrical Cable

- These cables are designed to maintain electrical integrity and insulation properties in high-temperature scenarios, ensuring consistent and safe power transmission.

Heat Resistant Single Core Cable

- Our Single Core Cables are perfect for applications requiring minimal wiring and maximum heat resistance, providing superior performance in confined spaces.

Heat Resistant Flexible Cable

- With enhanced flexibility and durability, these cables are suitable for dynamic applications where frequent movement and high temperatures are involved.

Heat Resistant Power Cable

- Designed for high power transmission, our Heat Resistant Power Cables ensure optimal functionality and safety in high-temperature environments.

Heat Resistant Silicone Cable

- Known for their exceptional thermal stability, our Silicone Cables offer reliable performance in both high and low-temperature applications.

Sizes of Heat Resistant Cables

5 Heat Resistant Cable

- This size is ideal for medium power applications, offering excellent thermal stability and electrical conductivity.

3 Core Heat Resistant Cable

- Suitable for three-phase power supply systems, these cables provide robust performance and heat resistance.

3 Core Heat Resistant Flexible Cable

- Combining flexibility with heat resistance, these cables are perfect for applications requiring movement and resilience to high temperatures.

4 Core Heat Resistant Cable

- Ideal for complex wiring systems, these cables ensure reliable performance and safety in high-temperature environments.

4 Core Heat Resistant Flex Cable

- Offering the benefits of both flexibility and heat resistance, these cables are suitable for dynamic and demanding applications.

5 Core Heat Resistant Flex Cable

- Designed for more intricate electrical systems, these cables provide excellent heat resistance and flexibility.

6 Core Heat Resistant Cable

- Perfect for advanced electrical systems, our six core cables offer superior performance and reliability under extreme temperatures.

Heat Proof Cable and Wire Manufacturer

As a trusted Heat Proof Cable and Wire Manufacturer, we provide cables that can withstand high temperatures without compromising their performance. These cables are essential for environments where constant exposure to heat is a challenge, ensuring optimal functionality and safety.

Heat Resistant Electrical Cables and Wires Manufacturer

Our range includes Heat Resistant Electrical Cables and Wiresthat maintain their integrity and insulation properties even in high-temperature scenarios. These cables ensure consistent and safe power transmission, making them indispensable for various critical applications.

Heat Resistant Single Core Cable Manufacturer

M.E.M. Industries is a renowned Heat Resistant Single Core Cable Manufacturer. Our single core cables are designed for applications that require minimal wiring while offering maximum heat resistance, providing superior performance even in confined spaces.

For applications requiring flexibility and durability, we offer Heat Resistant Flexible Cables. These cables are perfect for dynamic environments where frequent movement and high temperatures are common, ensuring reliable performance and longevity.

Heat Resistant Power Cable Manufacturer

As a prominent Heat Resistant Power Cable Manufacturer, we design cables for high power transmission, ensuring they function optimally and safely in high-temperature environments. Our Power Cablesare crucial for maintaining efficient energy distribution in demanding conditions.

Heat Resistant Silicone Cable Manufacturer

Our expertise extends to being a Heat Resistant Silicone Cable Manufacturer. Our Silicone Cablesare known for their exceptional thermal stability, offering reliable performance in both high and low-temperature applications. These cables are ideal for situations where extreme temperatures are a constant factor.

2.5 heat resistant cable manufacturer

M.E.M. Industries is also a leading 2.5 heat resistant cable manufacturer. This size is perfect for medium power applications, providing excellent thermal stability and electrical conductivity, ensuring efficient power distribution in various settings.

3 Core Heat Resistant Cable Manufacturer

We specialize as a 3 Core Heat Resistant Cable Manufacturer, providing cables suitable for three-phase power supply systems. These cables offer robust performance and heat resistance, making them essential for complex electrical setups.

3 Core Heat Resistant Flexible Cable Manufacturer

For applications requiring both flexibility and heat resistance, we are a trusted 3 Core Heat Resistant Flexible Cable Manufacturer. These cables combine flexibility with the ability to withstand high temperatures, making them perfect for dynamic and resilient applications.

4 Core Heat Resistant Cable Manufacturer

As a 4 Core Heat Resistant Cable Manufacturer, we offer cables ideal for intricate wiring systems. These cables ensure reliable performance and safety even in high-temperature environments, essential for complex electrical installations.

4 Core Heat Resistant Flex Cable Manufacturer

Our expertise includes being a 4 Core Heat Resistant Flex Cable Manufacturer. These cables offer the benefits of flexibility and heat resistance, making them suitable for demanding and dynamic applications that require resilience to high temperatures.

5 Core Heat Resistant Flex Cable Manufacturer

M.E.M. Industries is a trusted 5 Core Heat Resistant Flex Cable Manufacturer, designing cables for more intricate electrical systems. These cables provide excellent heat resistance and flexibility, ensuring optimal performance in complex environments.

6 Core Heat Resistant Cable Manufacturer

Lastly, we are a leading 6 Core Heat Resistant Cable Manufacturer, offering cables perfect for advanced electrical systems. Our Six Core Cables provide superior performance and reliability under extreme temperatures, ensuring efficient and safe power distribution.