EPR Cable

Home >> EPR Cable

EPR Cable Manufacturers

Mem Industries is engaged in Manufacturing a comprehensive range of EPR Cables. This range of EPR Cables is developed to match with the highest quality standards and norms. We are leading EPR Cables manufacturer and we ensure to provide good quality products to our customers. With firm commitment to quality, we are able to offered top quality EPR Cable. These cables are manufactured in compliance with the international quality standards and the current market demands. Supreme grade materials like annealed tinned copper and heat resisting elastomer is used in the manufacturing process to ensure high-grade end products. Our EPR Cable is widely demanded by our clients as it is compatible with any extreme condition.

Technical data as per IS: 9968 (Pt-1) and IS:6380-1984

- Temperature range: -55 degree centigrade to 90 degree centigrade Continuous

- Temperature range: -55 degree centigrade to 250 degree centigrade Short term

- Rated voltage: Upto 1100 volts

- Test voltage: 3000 volts for 5 minutes

- Insulation Resistance: 20 Megohms / Km at 20 deg C

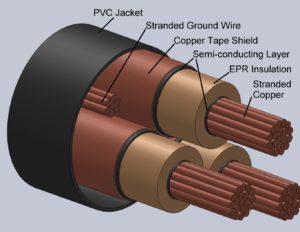

CABLE CONSTRUCTION

- Conductor Material : Annealed Tinned Copper wires having 99.96% purity

- Conductor Type: Class -5 flexibility as per IS: 8130-1984

- Insulation: EPR type IE1 and IE2 (IE-1 is General type & IE-2 is Heat Resistance type)

- Sheaths [Inner / Outer] : CSP: -40 deg C to 90 deg C, PCP: -40 deg C to 70 deg C

EPR- Ethylene Propylene Rubber is widely used as an insulation material for electric cables due to its high di-electric strength and is also used as sheath material due to excellent Ozone and weathering resistance.

EPR cables have the advantage of greater high frequency loss which can protect motors and transformers generated by variable speed drives and power system switching devices such as vacuum and SF 6 switches and circuit breakers. Mem Industries is the leading Manufacturers of EPR Cable.

Application

Drum Reeling/Unreeling, Trailing, Festooning, Mobile machines, Cranes, Coal handling, Material handling and Conveyor belts etc.

Case Study of EPR / PCP Cable

1) JSPL – ANGUL -RMHS SITE

We supplied them few sizes of EPR /PCP cables for RMHS wagon tripper application. We found that the outer sheath of the cable was cracking and kin short time the cores would also crack there by short circuiting the cables or missing the continuity dur to snapping of conductor.

The point of thought was that the same cables were performing well in other sites i.e. BAR MILL area and SMS zone. One scrutinizing the matter in detail, it was discovered that the raw material being unloaded was lime which had adverse effect on the Rubber insulation and sheath. The design was changed to improvise by providing double sheath with cotton cloth in between and Nylon yarn braiding. The sheath thickness were also increased to enhance the life of the cable

2) ELECTRO STEEL STEELS LTD (VEDANTA) BOKARO – SMS ZONE

We supplied them 4c x 25 sq. mm EPR / PCP cable for drum reeling & unreeling application wherein the cores use to get snapped off after few months. This process was a continual process and replacement of cables so frequently would be a cost factor. On studying the case in detail, we came out with a solution to provide one stainless steel wire rope of same size as of power cores. The idea was that the stainless steel wire rope would act as a shock absorber and on installing the said design, it was a successful story. Today we are regularly supplying this case to them and they are running the process without any further problem.