Heat Resistant Cables

Home >> Heat Resistant Cables

Heat Resistant Cables Manufacturers

Power cable for LT usage, suitable for high temperature (400°C) are available in required cross sectioned area and in 2, 3 and 4 core. These cables are used for two voltages electrical power stations, Indoors and Outdoors. High Temperature Cables, Electric Cables offered find application as power cables in plants having high temperature environment where it is not possible to use ordinary PVC cables.

Some of these high temperature areas include near furnaces, boilers, rotary kilns and others. The high temperatures around furnace frequently damage the electrical wiring of motors, control panels that requires replacement of cables at periodic intervals which in turn leads to precious loss of productivity.

We are counted among the leading of a wide array of Heat Resistant Cables manufacturers. All our products are manufactured under the close supervision of experienced professionals using high-grade material. The material used in the production process is sourced from vendors of high repute. Our range is applauded for its excellent performance, fire resistance, fine finishing, durability and high strength. Get best price of Heat Resistant Cables Manufacturers.

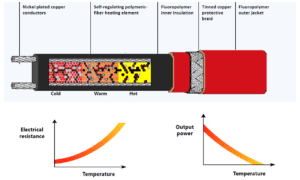

Here, the High temperature PTFE insulated Heat Resistant Cables offered by us are made using PTFE insulation that is an insulating material used for high temperatures and has excellent electrical properties with other advantages including inertness to almost all chemicals and does not age as well. All these properties make the insulation suitable to be used in high temperature power cables.

Here, our expertise in high-temperature materials assist customers in selecting right cables for meeting demanding high-temperature needs for control and power applications. With the range of single core and multi-core cables provided for temperatures ranging from-190°C to +1565°C

High Temperature Resistant Non Flammable Cables

- Applicable Standards : JSS: 51034, IS: 9968 (Pt-1), IS:8130-1984, BS:5308 (Pt-2) & IS:1554 (Pt-1)

- Voltage grade: upto 1100 volts

- Conductor size: 0.50, 0.75, 1.0, 1.5, 2.5, 4, 6, 10, 16, 25 sq.mm up to 240 sq.mm

- Conductor Materials: Annealed Bare Copper / Tinned Copper/ Silver plated Copper and Nickel plated Copper

- Heat Barrier Tape: Ceramic Glass Mica tape / Kapton Tape /Polyimide Tape

- Insulation : PTFE (260 deg C), FEP (205 deg C), Silicone Rubber(180 deg C), Fiber Glass (600 deg C), Ceramic Glass Mica (800 deg C)

- Screening / Shielding : Aluminium-Mylar tape with ATC drain wire / Silver Plated Copper wire braided / Nickel Plated Copper wire braided

- Armouring : Stainless Steel wire Braided type Flexible

- Inner / Outer Sheath : PTFE (260 deg C), FEP (200 deg C), Silicone Rubber(180 deg C), Asbestos Yarn (400 deg C), Fiber Glass (600deg C), Ceramic Glass Mica (800 deg C)

- Maximum Temperature with Standing Capacity : upto 800 deg C

SPECIAL FEATURES

- Available in multiple Insulations having different properties & various temperature range.

- Available from -73 deg C to 800 deg C range

- Hi Di-electric Strength

- Excellent Flame and Heat Resistant properties

- Available with Non-Flammable properties

- Available both Screen & Unscreen type

- Available both Armoured and Unarmoured type

- High Insulation Resistant

- Flexible and versatile

- High Mechanical strength

- U.V. Resistant

- Oil, Chemical, Moisture and Corrosion Resistant

- Excellent Thermal stability

- Halogen-Free Insulating materials such as PTFE / FEP/ ETFE / Silicone Rubber

SPECIAL INSULATING MATERIALS

| INSULATIONS | TEMPERATURE RANGE | PROPERTIES |

| Alumina Fiber | -73 deg C to 1200 deg C | Excellent Temperature Resistant |

| Ceramic Fiber | -73 deg C to 800 deg C | Excellent Temperature Resistant |

| Ceramic Glass Mica | -70 deg C to 800 deg C | Excellent Heat Resistant |

| Polyamide | -267 deg C to 310 deg C | Thin insulation, different colors available, Flame retardant |

| PTFE | -100 deg C to 260 deg C | High temperature resistant, Non-Flammable, Chemical and Oil resistant, excellent Di-electric strength |

| FEP | -80 deg C to 200 deg C | Chemical and Oil resistant, High Di-electric strength |

| Silicone Rubber | -40 deg C to 180 deg C | Highly flexible, Radiation resistant, high temperature resistant |

| Fiber Glass Yarn | -70 deg C to 600 deg C | High temperature resistant |

| Asbestos Yarn | -70 deg C to 400 deg C | High temperature resistant, good abrasion resistant |

HTC-909-300

Sintered PTEF – Sintered PTEF – S.S. Wire

Specification

- Voltage grade: upto 1100 volts

- Conductor: Bare Copper / Nickel Plated Copper / Silver Plated Copper

- Type: Multi Stranded Flexible

- Core Insulation: Sintered PTFE with Kapton

- Construction: Twisted cores / Laid up cores

- Outer Sheath: Sintered PTFE

- Overall Coverage: Fiber Glass Covering [Optional]

- METAL Braiding: Stainless Steel wire mesh for Mechanical protection [Optional]

Other Options

- Aluminium Mylar Tape Shield / Screen with ATC drain wire

- Overall Asbestos Braiding for Better Chemical & Heat Resistance

- Colour coding as per customised requirement

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm.

- Number of Cores available: 1C to Multicore as per customised requirement

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-918-400

Sintered PTFE – Fiber Glass – Fiber Glass – S.S. Wire

Specification

- Voltage grade up to 1100 volts

- Conductor: Bare EC Copper /Nickel Plated Copper/ Silver Plated Copper

- Type: Multi stranded flexible

- Core insulation: Sintered PTFE / Fiber Glass with high temperature varnish

- Construction: Twisted Cores / Laid up cores

- Inner jacket: Sintered PTFE & then Glass Plated Mica Tape

- Outer jacket: Fiber Glass Braiding / Asbestos Yarn Braiding

- Metal braiding: Stainless Steel wire mesh for Mechanical protection [Optional]

Other Options

- Aluminium mylar tape Shield / Screen with ATC drain wire

- Overall Asbestos Braiding for Better Chemical & Heat Resistance

- Colour coding as per customer requirement

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm.

- Number of cores available: 1C to multicore as per customer requirement

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-927-400

Sintered PTFE – Sintered PTFE – Mica – Fiber Glass – S.S. Wire

Specification

- Voltage grade : up to 1100 volts

- Conductor: Bare Copper / Nickel Plated Copper / Silver Plated Copper

- Type: Multi stranded Flexible

- Core Insulation : Sintered PTFE with Kapton

- Construction : Twisted core / Laid up Cores

- Inner jacket : Sintered PTFE Tape then Glass Mica Tape

- Outer jacket : Glass Mica Tape and then Fiber Glass with high temperature varnish

- Metal Braiding : Stainless Steel wire mesh for Mechanical protection [Optional]

Other Options

- Aluminium mylar tape Shield / Screen with ATC drain wire

- Overall Asbestos Braiding for Better Chemical & Heat Resistance

- Colour coding as per customised requirement

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm.

- Number of cores available: 1C to Multicore as per customer requirement

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-936-500

Sintered PTFE – Fiber Glass – Mica – Fiber Glass – S.S. Wire

Specification

- Voltage grade : up to 1100 volts

- Conductor: Bare Copper / Nickel Plated Copper / Silver Plated Copper

- Type : Multi stranded

- Core Insulation : Mica / Sintered PTFE / Kapton Fiber Glass with high temperature varnish

- Construction : Twisted core / laid up cores

- Inner jacket : Glass Plated Mica Tape and then Fiber Glass with high temperature varnish

- Outer jacket : Fiber Glass then Asbestos Yarn Braiding

- Metal Braiding : Stainless Steel wire mesh for Mechanical protection [Optional]

Other Options

- Aluminium mylar tape Shield / Screen with ATC drain wire

- Overall Asbestos Braiding for Better Chemical & Heat Resistance

- Colour coding as per customised requirement

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm.

- Number of cores available: 1C to Multicore as per customer requirement

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-945-600

High Temperature Copper Power Cable suitable for 600 deg C

Specification

- Voltage grade : up to 1100 volts

- Conductor: Multi stranded Annealed Electrolytic grade copper as per class – 5 of IS:8310-1984

- Primary Insulation: Mica tape then Sintered Teflon (PTFE) with Kapton

- Secondary Insulation : Heat & flame Resistant double Fiber Glass covering with heat resistance varnish

- Core Laying: Core Laid up together

- Inner Sheath: Sintered Teflon (PTFE)

- Outer Sheath: Double Mica tape, Double Fiber Glass Braiding, Asbestos Braiding

- Mechanical Protection : Stainless Steel Braided to protect the cable from Mechanical Stress

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm. from single core to multi core

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)

HTC-954-800

High Temperature Copper Power Cable suitable for 800 deg C

Specification

- Voltage grade : up to 1100 volts

- Conductor: Multi stranded Annealed Electrolytic grade copper as per class – 5 of IS:8310-1984

- Primary Insulation: Mica tape then Sintered Teflon (PTFE) with Kapton

- Secondary Insulation : Heat Resistant Mica Tape and then Ceramic Fiber

- Core Laying: Core Laid up together

- Inner Sheath: Sintered PTFE then Ceramic Glass Fiber covering with Glass Mica Tape

- Outer Sheath: Double Ceramic Glass Fiber Braided

- Mechanical Protection : Stainless Steel wire Braided to protect the cable from Mechanical Stress

- Sizes available: 0.5 / 1 /1.5 / 2.5 / 4 / 6 / 10 / 16 / 25 sq.mm. from single core to multi core

- Standards applicable: IS: 8130, IS: 1554 (Pt-1), JSS : 51034, BS : 5308 (Pt-1)