Screen Cables

Home >> Screen Cables

Screen Cables Manufacturers

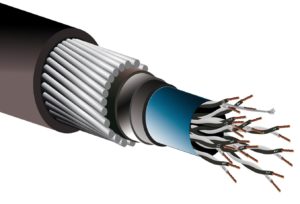

A Screen Cable is an electrical cable of one or more insulated conductors enclosed by a common conductive layer. With increase in demand of these wires. We have our in house manufacturing and testing facility for Screen Cables.

Screen Cables are available in both copper/ Aluminium foil shielding. We can supply copper screened with tinned coated copper wire and bare copper screened wires as well as per customers’ requirements. We put our best efforts in offering unmatched quality services that generate optimum value for the money invested by our clients Fulfilling the requirements of our clients within the required time frame is the first priority of our organization Queries of our clients are effectively handled by a team of proactive client support professionals Also feedback from our clients are well considered to make improvisations in our services. We are reputed Screen Cables Manufacturers.

What are Screen Cables ?

Screen Cables manufacturers are the type of cable which consists of multiple conductors which help in conveying signal with low energy signature mainly used for monitoring and controlling electrical system, power control and other processes associated with it. Such cables which are used in applications apart from power transmission also carry out important functions which help in smooth functioning of the process industries. Screen Cables Also is microprocessor based or computerized is instrument system. These cables are basically designed without interruptions and interference from external sources.Application of Screen Cables

Screen Cables find applications majorly in Control and Communication applications. These cables are mainly used in process industries where a lot of systems are involved. Screen Cables are involved in Process Control, Communication of analogue signals or digital signals and voice transmission signalling in Industrial and process control circuitry. These cables are mainly used in process industries such as Oil and Gas, Petrochemicals, Fertilizers, Cement, Paper, Steel, Aluminium, Power plants, etc. Screen Cables can face high amount of electromagnetic interference which can lead to inaccurate transfer of signals. To avoid such unwanted interference certain rules need to be followed so that these cables experience less effect due to EMI. Screen Cables need to be as far away from Power cables as possible. They can be laid in separate ways to avoid cross take. If it is not possible to keep distance between Power cables and Instrument cables, then both cables should be laid in such a way that they cross each other at right angles. Loops formed on instrument wiring can cause interference, hence should be avoided while installing the cables. Screen Cables need to be provided with Shielding/ Screening over the cables to avoid external interferences. These cables, conductors /cores are twisted together to form a pair. Individual pairs are shielded with aluminium-mylar foil with annealed tinned copper as Drain wire. In case of multiple cables, another similar shielding / screening is provided over all the collective screened pairs to ensure better shielding. The function is to provide protection to the data that is being transferred through these cables from external electromagnetic as well as electrostatic interference. Loss of data due to EMI is an undesirable effect and can be avoided by using shielded / screened cables. Shielding inside the cable is capable of reflecting the energy of the cable as well as the pickup noise generated by the cable and conducted to the ground. Due to such characteristics EMI does not infiltrate the shielding and cannot reach the conductor in any case. There are two types of shielding / screening namely Aluminium Foil with Drain wire type and Copper wire braided type shielding / screening.Additional Features

- Maximum temperature range – 40 degree centigrade to 105 degree centigrade

- Higher temperature range also available up to 800 degree centigrade

- Flame retardant, Low smoke with Halogen Free properties are available

- Oil, Chemical, Moisture, and Corrosion resistant available

- UV resistant

- Armoured/ Unarmoured available

- Control cables with screening available

- Both Aluminium-Mylar type with Drain wire and ATC wire Braided type screening available

- Available in different voltage grades like 300V, 500V, 600V, and 1100V

- Low di-electric losses

- High Insulation resistance up to 1,00,000 Ohms/km also available

- High mechanical strength

- Fire Survival with circuit integrity properties also available

- Flexible and versatile

- Available in Indian Standard and other International Standard Colour codings

Screen Cables (Signal / RTD Triad)

- Applicable Standards : BS:5308 (Pt-2) IS:5608 (Pt-3), VDE:0815, EN-50288& IS:1554(PT-1)

- Voltage grade: upto 1100 volts

- Conductor size: 0.50 TO 2.5 sq.mm up to 48 Pairs/Triods

- Conductor Materials: With 99.96% purity – Annealed Bare Copper, Tinned Copper, both standard and solid electrolytic grade wires.

- Insulation : PVC (type A-70 deg C/ type C-85 deg C/ 105 deg C) / Polyethelene 90 deg C / SPTFE 260 deg C / XLPE 90 deg C / FEP 200 deg C

- Screening / Shielding : Aluminium-Mylar tape with ATC drain wire or Annealed Tinned Copper Wire Braiding Both Individual Pair / overall or Only overall shielding / Screening Available

- Armouring : Both Galvanized Steel Round wire / flat strip or S.S. wire Braided type available

- Inner / Outer Sheath : PVC ST-1(70 deg C), PVC ST-2(90 deg C), FRLS type(90 deg C), LSZH type (90deg C) / Sintered PTFE (260 deg C) / Fiber Glass (600deg C) / Asbestos (500 deg C) / FEP (200 deg C)

- Twisting : Core twisting in Pair / Triads

- Rip cord : For easy removal of inner Sheath

- Communication Pair: Provided on request

Special Features of Signal Cables

- Low capacitance Signal and Communication cables

- Oil, Corrosion and Moisture resistant cables

- Superior Low Temperature properties

- High Insulation resistance cables

- High Temperature signal cables

- Highly Flexible signal cable available

- UV resistant sheath cables

- Low dielectric losses

- Fire Survival signal cables also available

- Ozone resistant

- Small Bending Radius

| Mutual Capacitance (PE) | Mutual capacitance (PVC) | L/R Ratio | ||||

| Conductor Size | Conductor Resistance at 20 degree C | Core to Core | Core to Screen | Core to Core | Core to Screen | |

| Sq.mm | Ohm/km | pF/mtr | pF/mtr | pF/mtr | pF/mtr | mH / Ohm |

| 0.50 | 39.70 | 75 | 115 | 250 | 400 | 25 |

| 0.75 | 26.50 | 75 | 115 | 250 | 400 | 25 |

| 1.0 | 18.60 | 75 | 115 | 250 | 400 | 25 |

| 1.5 | 12.30 | 85 | 120 | 250 | 400 | 40 |

| 2.5 | 7.41 | 85 | 120 | 250 | 400 | 60 |

Characteristics of Screen Cables

| Conductor sizes | 0.5 sq.mm | 0.75 sq.mm | 1.0 sq.mm | 1.5 sq.mm | 2.5 sq.mm | Unit | |

| Mutual capacitance core to core / core to screen (with PVC insulation) | < | 250/400 | 250/400 | 250/400 | 250/400 | 250/400 | pF/ Mtr |

| Mutual capacitance core to core / core to screen (with Polyethylene/XLPE insulation) | < | 75/115 | 75/115 | 75/115 | 85/120 | 85/120 | pF/ Mtr |

| L/R Ratio | 25 | 25 | 25 | 40 | 60 | μH/ Ohm | |

| Conductor to DC Resistance at 20 degree centigrade | < | 39.70 | 26.50 | 18.60 | 12.30 | 7.41 | Ohm/ Km |

| Insulation resistance with PVC core insulation | > | 100 | 100 | 100 | 100 | 100 | M Ohm/ Km |

| Insulation resistance with polyethylene/XLPE core insulation | > | 5000 | 5000 | 5000 | 5000 | 5000 | M Ohm/km |

| Core to core/core to screen/screen to armour insulation resistance at 500V (PVC) | > | 25 | 25 | 25 | 25 | 25 | M Ohm/km |

| Screen to screen insulation resistance at 500V | > | 1 | 1 | 1 | 1 | 1 | M Ohm/km |

| HV Test for 1 minute: Core to core | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | Kv | |

| HV Test for 1 minute: Core to screen | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | Kv | |

| HV Test for 1 minute: Screen to armour | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | Kv |