Fire Survival Cable

Home >> Fire Survival Cable

Fire Survival Cable Manufacturers

In the event of a fire, the biggest obstacles to safe evacuation are smoke, heat, and toxic fumes. To mitigate these hazards, it is crucial to use fire-resistant and non-halogenated cables. MEM Industries has added a special range of Fire Survival & Fire Resistant cables to its product portfolio. Our Fire Survival Cables are designed to remain operational for a minimum duration during a fire, even when exposed to water spray and mechanical shock. Our Fire Survival Cablesare rigorously tested in NABL accredited labs like ERDA Baroda to ensure the highest quality products. These cables are vital for ensuring the safety of people and property, particularly in areas prone to fire hazards. As one of the leading Fire Survival Cables Manufacturers, MEM Industries provides a comprehensive range of high-quality fire-resistant cables that meet various industry standards and regulatory requirements.

Every year there are a lot of fire accidents across the country which claims a lot of human lives and property. The deaths are not caused because of fire burns alone. It is because of inhaling the deadly HCL gas which emits from the normal cable wiring and also smoke generated by burning of PVC cables and other items. The people trapped in the fire zone get choked because of the smoke and moreover the fire alarm system and other such important cables get damaged due to fire. Mem Industries is the high quality This can be prevented by using Fire Survival Cable Manufacturers which have the following special properties:

- Can withstand continuous Flame environment having temperature of upto 950 deg C for 3 hours which is an enough time to escape.

- The fire alarm system does not get disconnected thereby alarming the people to evacuate

- This cable emits negligible smoke due to which the visibility is clear for escaping and protecting the property. Moreover, people do not get choked due to negligible smoke emission.

- When the cable comes in contact with fire, the HCL gas emission is zero thereby protecting human lives and does not hinder the fire fighting system.

- The cable ensures circuit integrity for 3 hours at 950 deg C flame environment thereby protecting loss of continual data flow in process industry.

- Stranded Copper conductor having 99.96% purity

- Insulated with specially formulated Elastomeric compound on each conductor

- Cores are laid up / twisted together to form pair / triad

- Overall Fire resistant binder tape

- Inner sheath of LSZH compound

- Shielding / Screening of Aluminium mylar tape with ATC drain wire provided overall as well as on individual Pair / Triad also.

- Armouring provided as per requirement

- Outer sheath of LSZH compound to withstand 3 hours of Flame temperature between 750 deg C to 950 deg C

- Fire Survival test conducted as per IEC-60331

SPECIAL FEATURES

- Maintains high integrity during and after fire

- High tensile strength

- Water resistant

- Chemical resistant

- Withstands flame temperature between 750 deg C to 950 deg C for 3 hours

- Does not emit noxious smoke and fumes which helps easy fire fighting and saving life and property

- Does not propagate flame

- Standards applicable: IEC-331 / BS 6387 / IEC-60331

- Availability: Thermocouple Compensating cables, Instrumentation signal cables, Control cables, Power Cables, Foundation FieldBus Cables etc

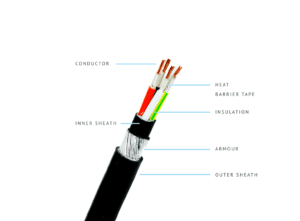

CABLE CONSTRUCTION

- Applicable Standards: BS 6387, IEC: 60331, BS:5308 (Pt-2) & IS:1554 (Part-1)

- Voltage Grade: 600 volts / 1100 volts

- Cable Type: Single Core / Pair / Triad and Multi-Core / Multi-Pair / Multi-Triad

- Conductor Type: Multi stranded / stranded / solid

- Conductor Material: Annealed bare Copper / Tinned Copper

- Fire Barrier Tape: Ceramic Glass Mica tape

- Core Insulation: Silicone Rubber or Cross Linked Polyolefin Elastomer

- Cores Laying / Twisting: Cores laid up together or twisted into Pair / Triad

- Screening/ Shielding: Individual Pair / Triad and or Overall

- Screen Material: Aluminium Mylar tape or Copper tape with ATC drain wire or Braiding with Tinned Copper / NPC Copper / SPC Copper

- Inner & Outer Sheath: LSZH or equivalent

- Armouring: Galvanized steel Round wire / Flat Strip