Instrumentation Cables

Home >> Instrumentation Cables

Instrumentation Cables Manufacturer

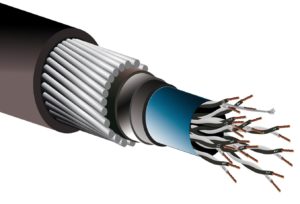

At MEM Industries, we take pride in being a top Instrumentation Cables Manufacturer, offering high-quality cables that ensure accurate and reliable signal transmission in critical industrial and commercial applications. Our instrumentation cables are engineered to meet stringent industry standards, providing you with durable and dependable solutions.

High-Performance Instrumentation Cables for Precision Control

Instrumentation cables play a vital role in transmitting signals that monitor and control electrical systems. At MEM Industries, our cables are designed to deliver precise signal transmission, ensuring that your systems function efficiently and effectively, even in challenging environments.

Instrumentation Tray Cable Manufacturer

MEM Industries specializes in manufacturing Instrumentation Tray Cables that offer superior protection and performance in industrial settings. These cables are specifically designed for installation in trays, ducts, or conduit systems, providing reliable signal transmission while withstanding harsh conditions.

Our instrumentation tray cables are equipped with robust insulation and shielding to prevent signal interference, ensuring that your control systems operate with the highest level of accuracy. Whether you need cables for power plants, manufacturing facilities, or any other industrial environment, MEM Industries has you covered.

Why Choose MEM Industries for Instrumentation Cables?

- Precision Engineering: Our cables are crafted to deliver accurate signal transmission, crucial for the smooth operation of your control systems.

- Durability: Built to last, our instrumentation cables are resistant to harsh environmental conditions, including moisture, chemicals, and extreme temperatures.

- Versatility: MEM Industries offers a wide range of instrumentation cables, suitable for various industrial applications.

- Custom Solutions: We provide customized cable solutions to meet the specific requirements of your projects.

Additional Features

- Maximum temperature range – 40 degree centigrade to 105 degree centigrade

- Higher temperature range also available up to 800 degree centigrade

- Flame retardant, Low smoke with Halogen Free properties are available

- Oil, Chemical, Moisture, and Corrosion resistant available

- UV resistant

- Armoured/ Unarmoured available

- Control cables with screening available

- Both Aluminium-Mylar type with Drain wire and ATC wire Braided type screening available

- Available in different voltage grades like 300V, 500V, 600V, and 1100V

- Low di-electric losses

- High Insulation resistance up to 1,00,000 Ohms/km also available

- High mechanical strength

- Fire Survival with circuit integrity properties also available

- Flexible and versatile

- Available in Indian Standard and other International Standard Colour codings

Instrumentation Cables (Signal / RTD Triad)

- Applicable Standards : BS:5308 (Pt-2) IS:5608 (Pt-3), VDE:0815, EN-50288& IS:1554(PT-1)

- Voltage grade: upto 1100 volts

- Conductor size: 0.50 TO 2.5 sq.mm up to 48 Pairs/Triods

- Conductor Materials: With 99.96% purity – Annealed Bare Copper, Tinned Copper, both standard and solid electrolytic grade wires.

- Insulation : PVC (type A-70 deg C/ type C-85 deg C/ 105 deg C) / Polyethelene 90 deg C / SPTFE 260 deg C / XLPE 90 deg C / FEP 200 deg C

- Screening / Shielding : Aluminium-Mylar tape with ATC drain wire or Annealed Tinned Copper Wire Braiding Both Individual Pair / overall or Only overall shielding / Screening Available

- Armouring : Both Galvanized Steel Round wire / flat strip or S.S. wire Braided type available

- Inner / Outer Sheath : PVC ST-1(70 deg C), PVC ST-2(90 deg C), FRLS type(90 deg C), LSZH type (90deg C) / Sintered PTFE (260 deg C) / Fiber Glass (600deg C) / Asbestos (500 deg C) / FEP (200 deg C)

- Twisting : Core twisting in Pair / Triads

- Rip cord : For easy removal of inner Sheath

- Communication Pair: Provided on request

Special Features of Signal Cables

- Low capacitance Signal and Communication cables

- Oil, Corrosion and Moisture resistant cables

- Superior Low Temperature properties

- High Insulation resistance cables

- High Temperature signal cables

- Highly Flexible signal cable available

- UV resistant sheath cables

- Low dielectric losses

- Fire Survival signal cables also available

- Ozone resistant

- Small Bending Radius

| Mutual Capacitance (PE) | Mutual capacitance (PVC) | L/R Ratio | ||||

| Conductor Size | Conductor Resistance at 20 degree C | Core to Core | Core to Screen | Core to Core | Core to Screen | |

| Sq.mm | Ohm/km | pF/mtr | pF/mtr | pF/mtr | pF/mtr | mH / Ohm |

| 0.50 | 39.70 | 75 | 115 | 250 | 400 | 25 |

| 0.75 | 26.50 | 75 | 115 | 250 | 400 | 25 |

| 1.0 | 18.60 | 75 | 115 | 250 | 400 | 25 |

| 1.5 | 12.30 | 85 | 120 | 250 | 400 | 40 |

| 2.5 | 7.41 | 85 | 120 | 250 | 400 | 60 |

Characteristics of Instrumentation Cables

| Conductor sizes | 0.5 sq.mm | 0.75 sq.mm | 1.0 sq.mm | 1.5 sq.mm | 2.5 sq.mm | Unit | |

| Mutual capacitance core to core / core to screen (with PVC insulation) | < | 250/400 | 250/400 | 250/400 | 250/400 | 250/400 | pF/ Mtr |

| Mutual capacitance core to core / core to screen (with Polyethylene/XLPE insulation) | < | 75/115 | 75/115 | 75/115 | 85/120 | 85/120 | pF/ Mtr |

| L/R Ratio | 25 | 25 | 25 | 40 | 60 | μH/ Ohm | |

| Conductor to DC Resistance at 20 degree centigrade | < | 39.70 | 26.50 | 18.60 | 12.30 | 7.41 | Ohm/ Km |

| Insulation resistance with PVC core insulation | > | 100 | 100 | 100 | 100 | 100 | M Ohm/ Km |

| Insulation resistance with polyethylene/XLPE core insulation | > | 5000 | 5000 | 5000 | 5000 | 5000 | M Ohm/km |

| Core to core/core to screen/screen to armour insulation resistance at 500V (PVC) | > | 25 | 25 | 25 | 25 | 25 | M Ohm/km |

| Screen to screen insulation resistance at 500V | > | 1 | 1 | 1 | 1 | 1 | M Ohm/km |

| HV Test for 1 minute: Core to core | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | Kv | |

| HV Test for 1 minute: Core to screen | 1.0 | 1.0 | 1.0 | 1.0 | 1.0 | Kv | |

| HV Test for 1 minute: Screen to armour | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | Kv |

Instrumentation Tray Cables Manufacturer

Instrumentation Tray Cables that are customizable in virtually endless options to fit your unique application requirements and specifications. M.E.M. Industries’ Instrumentation Tray Cables are engineered to meet or exceed application requirements for factory floor automation equipment, material handling, sensors and transducers, process controls and other applications.

Benefits

- UL listed and approved for CE Mark

- Compliant to ANSI, NEC, NFPA,

RoHS2 and REACH standards - Lower installation costs – no conduit needed

- Saves space – inherently smaller and less

expensive than standard tray cable - Designed and approved for wet installation

- Versatile -suitable for use in Class I, Div 2 areas

Instrumentation Tray Cable Features

M.E.M. Industries offers Instrumentation Tray Cables with the following characteristics:

- Multi-Conductors

- Foil and Braid Shields

- Twisted Shielded Conductors

- UL Rated

- UV Resistant

Instrumentation Tray Cable Materials

Instrumentation Tray Cables from M.E.M. Industries are available with the following materials:

- Polyvinyl Chloride (PVC)

- PVC/Nylon (VNTC)

- Thermoplastic Elastomer (TPE)

- Cross-linked Polyethylene (XLPE)

- Chlorinated Polyethylene (CPE)

- Hyperon

Instrumentation Tray Cable Technical Specifications

M.E.M. Industries offers Instrumentation Tray Cables in the following ranges of technical specifications:

- Gauge: 4/0 to 30AWG

- Voltage: 300V – 600V

- Temperature: Up to 150°C